Stainless Steel KSAT Saturated Hydraulic Conductivity Meter

The KSAT system from METER Group is a laboratory instrument engineered for measuring the saturated hydraulic conductivity (Kₛ or Ksat) of soil samples — one of the most challenging soil-physical parameters to determine reliably.

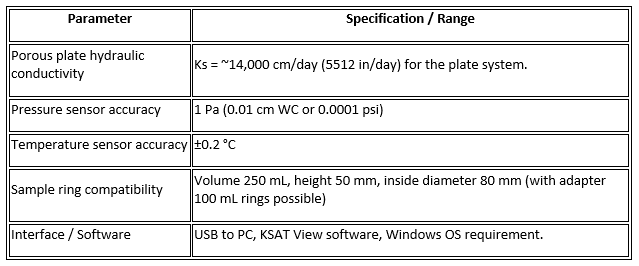

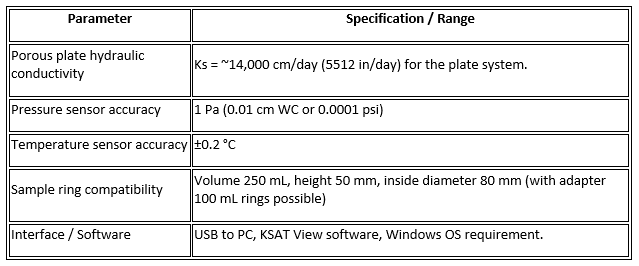

It incorporates both constant-head and falling-head testing methods in an automated, integrated package, thereby reducing human error and streamlining the workflow. The system is compatible with standard sample rings (e.g., 250 mL volume/80 mm diameter) and shares compatibility with other METER Group systems (e.g., HYPROP) to allow combined measurement of unsaturated and saturated hydraulic properties.

Key Feature /Highlights

- • Automated measurement of saturated hydraulic conductivity with both falling and constant head methods for soil cores.

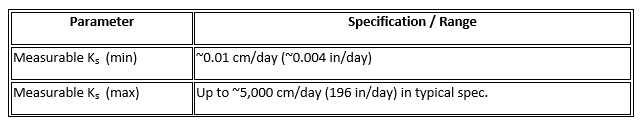

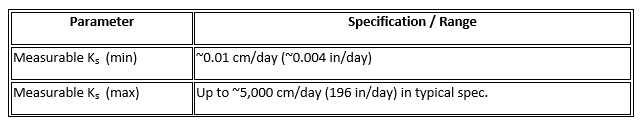

- • Wide measurement range: from as low as around 0.01 cm/day up to several thousand cm/day, enabling testing of soils from very low permeability to very high.

- • Built-in temperature sensor and software correction for temperature‐dependent water viscosity — ensuring more accurate conductivity values.

- • Compact bench footprint, fully integrated with software (USB connection, automated data capture) for ease of use.

- • Compliance with established standards (e.g., DIN 19683-9, DIN 18130-1, ASTM D2434) for saturated hydraulic conductivity measurement.

Technical Specifications

Application / Usage Areas

- • Soil physics laboratories: determining saturated hydraulic conductivity of undisturbed or remoulded soil cores as part of characterising soil hydraulic properties.

- • Agronomy & soil science research: combining measurements of unsaturated (soil-water retention) and saturated conductivity to model water movement in soils.

- • Environmental engineering: evaluating drainage, infiltration, groundwater recharge, contaminant transport in saturated soils.

- • Quality control in geotechnical investigations: verifying permeability of soil installations, liners, barrier materials.

- • Education and research institutions: providing hands-on measurement of Darcy’s Law in soils under saturated conditions.

Benefits / Users Advantages

- • Automation means fewer manual interventions (timing outflow, weighing beakers, estimating flow rates) — reduces operator error and increases throughput.

- • Wide measurement range allows flexibility across soil types from very low to high permeability.

- • Integration with standard soil-core rings, and compatibility with other METER systems (HYPROP) allows multi-property workflow (unsaturated + saturated) from the same sample, saving sample preparation time.

- • Precise measurement (with temperature correction and accurate sensors) yields trustworthy data for publication, engineering design or research.

- • Compact bench footprint and user-friendly software make it accessible for labs with limited space or staffing.

Best Practice & Consideration

- • Ensure soil samples are fully saturated before testing — any air in the core will bias conductivity measurements downward.

- • Use the correct sample ring size and ring-holder compatible with the KSAT system (250 mL volume / 50 mm height is typical).

- • Confirm soil core is of uniform cross-section and no side-wall leakage; seal properly to the ring holder.

- • For very low conductivity soils (near the lower limit), allow longer measurement times to stabilise flow and ensure steady‐state conditions are reached.

- • Calibrate the system according to manufacturer instructions (pressure sensor check, plate conductivity check, temperature sensor check) for optimal accuracy.

- • Bear in mind that the sample size (80 mm diameter, 50 mm height) limits the representativity of the measurement to the core volume – interpret results accordingly for field scale up.

- • Keep the water temperature stable during measurement (because viscosity is temperature‐dependent) and use the software’s temperature correction feature.